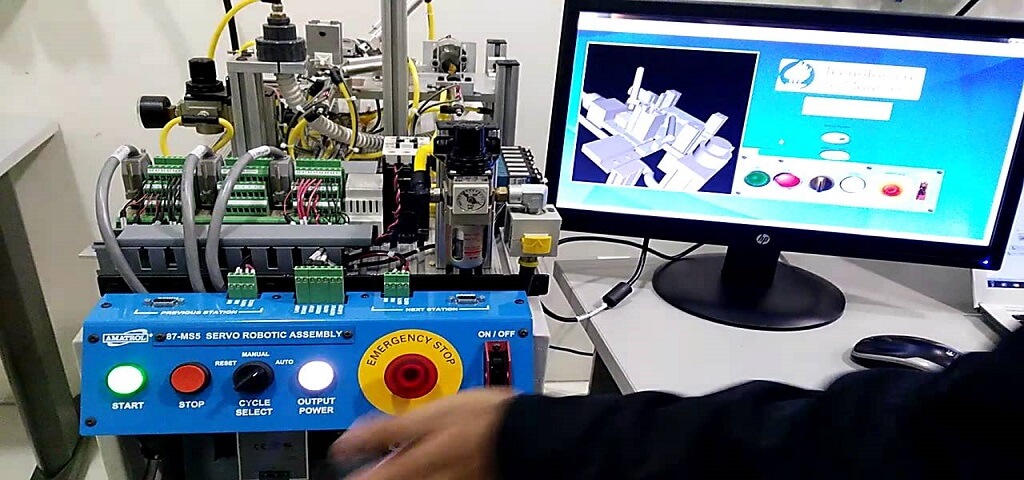

Virtual commissioning to be analysed during development of offline programming. Virtual layouts of complete manufacturing lines are engineered, commissioned and checked before the realization phase starts. During Virtual Commissioning both PLC and robotic processes are functionally simulated and verified through a 3D model to verify cycle time of the connected components and integrated new vehicle models in to existing production line in real time environment reducing shut down and plant maintenance significantly.

Optimize your automation systems and debug PLC programming in a virtual environment.

Today’s highly automated and flexible manufacturing systems are all controlled by programmable logic controller (PLC) programs that include sophisticated tooling, robots, transfer lines and other safety equipment. PLC programming allows manufactures to alter production lines without having to completely retool the entire facility. However, whenever changes are made, engineers still have to stop the production for an extended period of time while they debug the PLC programs against live equipment. With Tecnomatix virtual commissioning solutions, you can debug your PLC codes on a virtual environment before downloading them to real equipment. By simulating and validating your automation equipment virtually, you can test and validate that they will work as expected and significantly reduce system start-up time.